Pharmaceutical manufacturers will need to ramp up production capacity now that treatments are being found for the current pandemic. But how? Keith Tilley, CEO of Intoware, explains the ways workflow technology can help manufacturing progress in efficiency and compliance.

The Covid-19 pandemic may prove to be the greatest challenge since World War II. Our healthcare system is stretched to the absolute limit. Pharmaceutical manufacturers are under immense pressure to find new treatments and vaccines against this virus.

The response from pharma and biotech companies to finding a Covid-19 treatment has led to more than 1,000 clinical trials. Over 150 treatments are being tested. This is impressive given the virus was only discovered on the 31st December 2019. But the on-going challenge remains: How to boost production efficiency as new treatments are found?

Prior to the pandemic, we had seen increased interest from pharma manufacturers in our automation platform WorkfloPlus. It helps digitise their production processes. In our experience, the challenge faced by many manufacturers is their continued reliance on spreadsheets, word documents or even paper to complete their tasks. This may seem fine, but it fails to offer the accuracy or granularity that can be gained through digitising manufacturing operations. Imagine being able to see, for example, how long each task really takes. Additionally, imagine taking photos or videos to record information in real time. You could also access a process by scanning a barcode or calling for live-help if things need attention, all through a simple mobile device or headset?

Ensuring compliance

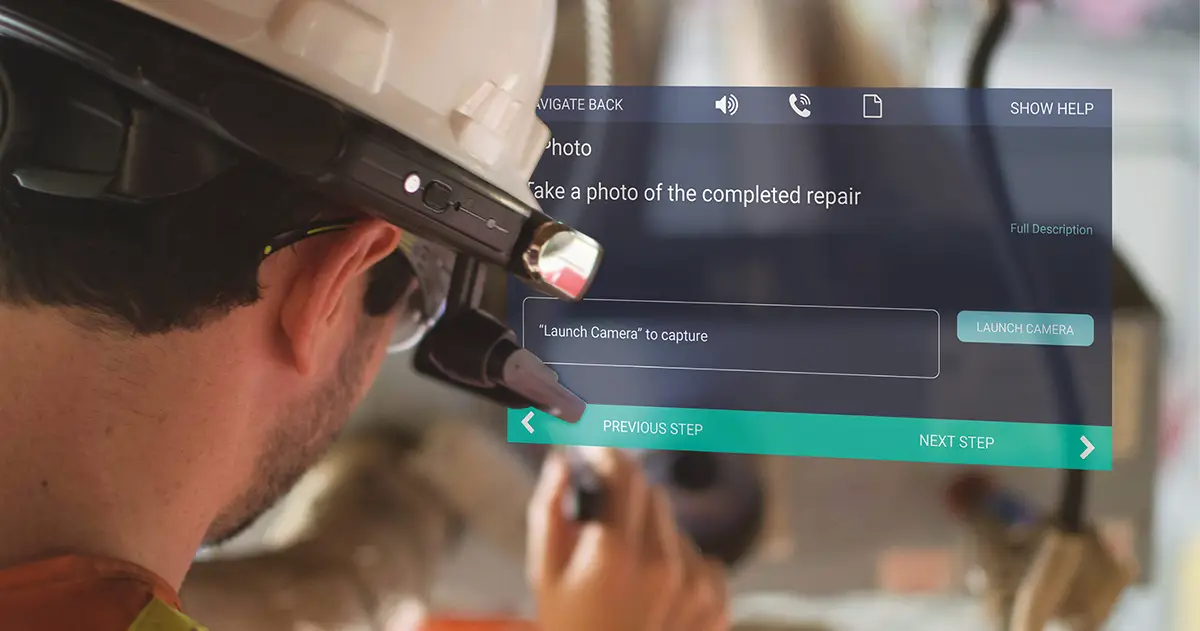

Intoware developed WorkfloPlus to help digitise workflow processes that need to be followed. Using both mobile and augmented reality (AR) technology, it ensures that a process can be consistently followed and audited. Furthermore, it provides the necessary data analytics to ensure compliance – ideal for highly-regulated industries such as the pharmaceutical. Better compliance is ensured by providing a thorough audit trail of what was done when and by whom. This is achieved by cataloguing every decision point and action in the manufacturing operations, reducing errors and improving productivity.

But what happens if the manufacturing landscape were to change quickly?

A single source of truth to enable manufacturing progress

The speed of change is rapid too. A change to the business process is sent to all users instantly, providing a “single source of truth”. Therefore, everyone is working off the same version. This means it’s easier to schedule downtime and manage production demands as things change. However, if relying on spreadsheets or written notes, this change could take many hours and inconsistencies.

Where humans are involved, errors too cannot be totally eliminated. But you can significantly de-risk your operation through automation. Additionally, if you have the audit trail that allows users to analyse the data at a highly-detailed level, you can make further enhancements to reduce risks.

Ultimately, workflow automation removes paper-based processes. It improves communication and collaboration to help free manufacturers from silo-based processes that are the result of ad-hoc systems.

One example is Bayer Pharmaceuticals. It tested and is now using WorkfloPlus with HMT headsets from Realwear to help streamline its production changeover process, in a highly-regulated market.

Drug manufacturing operation requires regular cleaning and changeovers between each batch. WorkfloPlus allows this procedure to be taken in a constant and timely manner. This helps minimise down-time for greater cost efficiency, whilst at the same time it provides a thorough audit check that a manual ‘tick-list’ could never deliver.

Whether it’s inefficient processes or poor compliance thanks to a reliance on ad-hoc systems. These are just some of the issues holding pharmaceutical manufacturing progress back from achieving the capacity needed to counter this pandemic – so the question should not be whether to automate, but when?