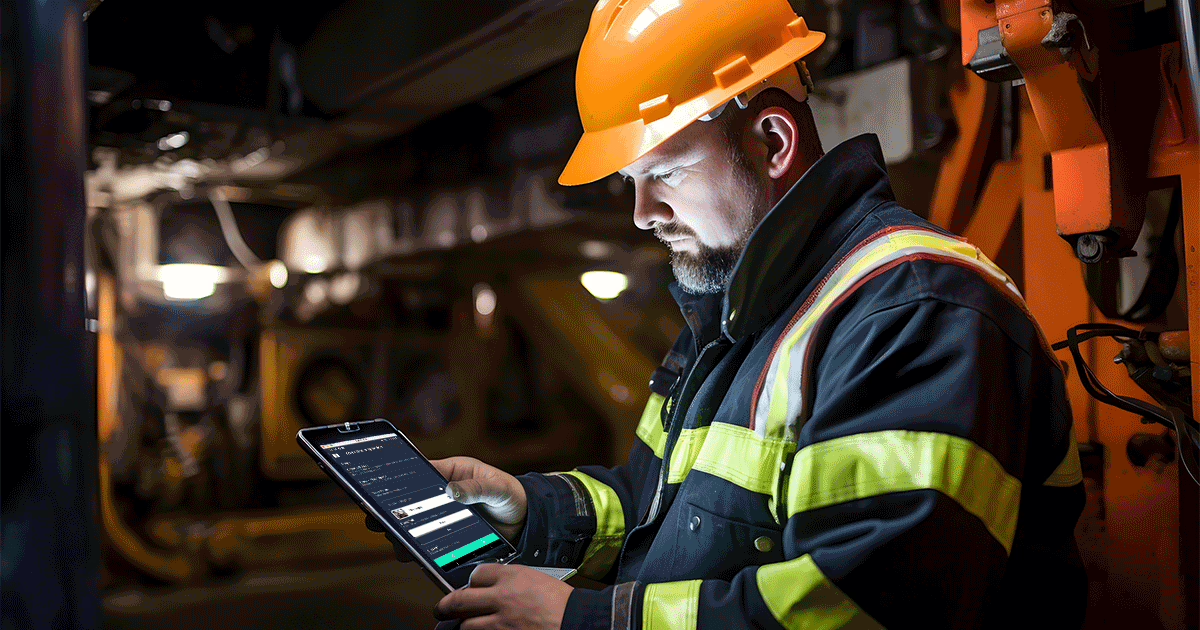

WorkfloPlus for mining digitises workflows, enhances compliance, and improves productivity, ensuring operations run seamlessly in even the most challenging environments.

The mining industry is under increasing pressure to improve productivity, enhance worker safety, and meet strict compliance requirements. Traditional paper-based processes can slow operations and introduce human error, creating inefficiencies and potential risks. This is where WorkfloPlus for mining steps in, by offering a digital transformation solution that streamlines workflows, ensures compliance, and boosts overall operational efficiency.

The Challenges Facing the Mining Industry

Mining operations are complex, often involving remote locations, hazardous environments, and stringent regulatory requirements. Common challenges include:

- Inefficient Paper-Based Workflows – Manual processes lead to delays, lost data, and human errors.

- Workforce Safety & Compliance – Strict health and safety standards require accurate record-keeping and real-time updates.

- Equipment Maintenance & Inspections – Scheduled and reactive maintenance must be logged efficiently to prevent costly downtime.

- Remote Workforce Management – Mining operations require teams to work in isolated areas with limited connectivity.

How WorkfloPlus for Mining Addresses These Challenges

WorkfloPlus is a digital workflow solution that replaces paper-based processes with smart, connected technology. By integrating WorkfloPlus for mining, companies can expect:

1. Enhanced Productivity and Efficiency

With WorkfloPlus, mining teams can access digital work instructions, checklists, and task assignments in real-time. This eliminates paperwork delays and ensures work is completed faster and more accurately. By digitising workflows you reduce the paperwork, allowing workers to focus on critical tasks.

2. Improved Safety and Compliance

Mining companies must adhere to strict safety regulations. WorkfloPlus ensures compliance by providing:

- Real-time digital audit trails for health and safety procedures.

- Mandatory safety checklists before tasks can be completed.

- Instant incident reporting to improve response times and prevent future risks.

3. Optimised Equipment Maintenance

Unplanned equipment failures can cause costly downtime. WorkfloPlus enables:

- Scheduled maintenance tracking with automated reminders.

- Digital logging of maintenance reports to ensure regulatory compliance.

- Real-time visibility into asset health, reducing unexpected breakdowns.

4. Seamless Connectivity for Remote Workers

Mining often involves teams working in isolated areas with limited connectivity. WorkfloPlus operates online and offline, ensuring that workers can access and input data regardless of their location. Once connectivity is restored, data is automatically synced to the system.

5. Data-Driven Decision Making

With WorkfloPlus, companies gain valuable insights from the automatically generated digital audit trails. Which allow managers to track performance metrics, identify process inefficiencies, and make data-driven decisions to optimise operations.

Why WorkfloPlus for Mining?

Implementing WorkfloPlus in the mining industry leads to:

- 30% faster task completion rates due to digital workflow automation.

- Increased compliance with fully traceable audit logs.

- Improved worker safety with real-time alerts and digital safety checklists.

- Reduced downtime through predictive maintenance and instant reporting.

Future-Proof Your Mining Operations

The future of mining is digital, and WorkfloPlus for mining is the key to unlocking safer, more efficient operations. By replacing outdated processes with digital workflows, mining companies can ensure compliance, improve productivity, and protect their workforce.

Are you ready to modernise your mining operations? Contact us today to learn more about how WorkfloPlus can help.