WorkfloPlus Digital Work Instructions

Digital work instructions are essential for ensuring operational efficiency, consistency, and safety.

WorkfloPlus revolutionises how organisations create, manage, and distribute processes and procedures, empowering employees to carry out tasks with confidence and precision.

By providing step-by-step guidance accessible via mobiles, tablets, desktops, or wearables, WorkfloPlus eliminates confusion and enhances productivity across operations, while capturing essential data for continuous improvement initiatives.

Streamline SOPs to increase operational efficiency and ensure quality.

WorkfloPlus streamlines the creation and management of digital work instructions for Standard Operating Procedures, ensuring that every team member can easily access up-to-date procedures. This accessibility reduces the risk of errors, enhances compliance with industry standards, and fosters a culture of accountability.

By digitising SOPs, teams can implement best practices more efficiently, leading to improved resource utilisation and waste reduction, ultimately enhancing your competitive edge.

Minimise equipment downtime between production runs and avoiding costly errors.

WorkfloPlus provides detailed digital work instructions that guide users through specific machine setup procedures, ensuring that equipment is configured correctly every time. This reduces human error and increases operational efficiency.

Plus, the automatically generated digital audit log of each setup allows for performance tracking and continuous improvement of setup processes, leading to higher productivity and optimal resource use

Ensure Consistent Quality Inspections and Avoid Costly Errors.

WorkfloPlus provides detailed digital work instructions that guide users through each step of the quality inspection process, ensuring that inspections are performed consistently and in accordance with set standards. This reduces human error, enhances compliance, and ensures that product quality is maintained.

Additionally, the automatically generated digital audit log of each inspection allows for real-time tracking, performance analysis, and continuous improvement, leading to higher product quality and optimal use of resources.

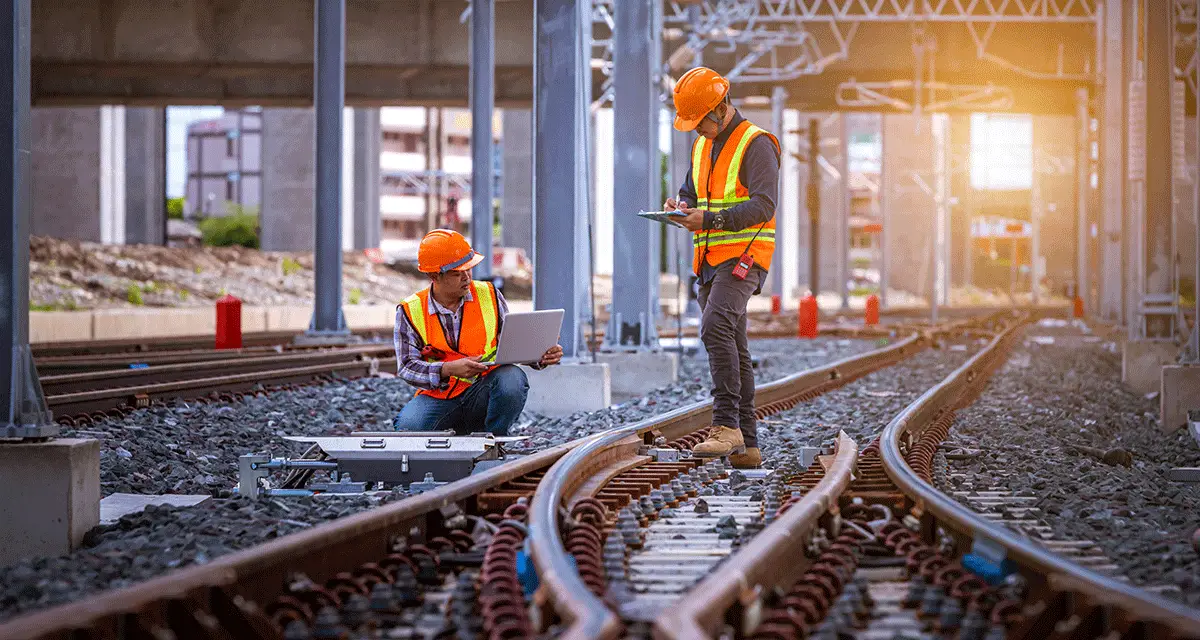

Keep equipment running smoothly and avoid costly breakdowns.

Digital work instructions created in WorkfloPlus speed up maintenance tasks, by providing detailed, step-by-step procedures to ensure nothing gets missed, increasing efficiency and safety.

By eliminating the need for paperwork and manual data entry, WorkfloPlus ensures accurate and up-to-date maintenance records which enables predictive maintenance scheduling. This helps companies to anticipate potential failures and reduce unplanned downtime.

Ensure every step is executed accurately with evidential capture throughout the process.

WorkfloPlus provides interactive checklists and visual guides to support workers in completing assembly tasks correctly, enhancing customer satisfaction and operational efficiency.

By capturing installation data, including timestamps and photographic evidence, teams can streamline customer sign-off processes and enhance service transparency. This reduces the likelihood of rework, boosts overall project efficiency and speeds up the payment cycle.

Accelerate knowledge transfer and enhance employee competency.

WorkfloPlus captures the knowledge of the most experienced employees to create engaging, interactive training programmes that can incorporate multimedia elements, catering to different learning styles.

This approach not only helps new employees grasp complex procedures more quickly but also standardises training across the organisation, ensuring that all team members receive consistent instruction.

Find out more in our eBook:

Getting started with WorkfloPlus is as easy as one - two - three.

Intoware’s customer success model ensures your project achieves it’s goals, and provides ROI as quickly as possible.

Engage

On our Discovery call, we’ll find out about you and your existing processes to learn exactly what you’re looking for.

Design

Configure your workflows. Customise templates with our toolkit or build processes from scratch.

Deploy

Integrate your digital workflows with existing devices. We’re on hand to help with training, support and integration.