Digital disruption has reshaped the business landscape. It’s a challenge to find a company that hasn’t either adopted or considered digitisation to connect their frontline workforce. This helps ensure future growth. That said, some sectors have seen more change than others, explains Intoware’s CEO, Keith Tilley.

Traditional industries such as utilities, manufacturing, oil and gas and infrastructure have been slower to act compared with newer tech or media businesses. When industries are reliant on outdated and paper-based processes, it results in process inefficiencies. This leads to weak decision making, intelligence hidden in silos, and an inability to attract new talent.

Connecting your frontline workforce, such as service engineers, maintenance technicians and assembly line workers to legacy business processes by going paper-less is a critical first step in creating a digital workplace. If you are looking to gain actionable insights from the data in your business for future growth, it means digitising critical paper-based, legacy, and human processes.

A frontline connected workforce strategy joins legacy systems and new digital technologies such as Cloud, AI, sensors, smart phones, tablets, and wearables. This ensures frontline industrial workers have the right information they need to do their jobs effectively. It empowers them by providing step-by-step digital work instructions. Also, it gives access to live video, audio, and photos, which they can share with experts here or globally to solve problems instantly.

Want to make savings from a connected workforce?

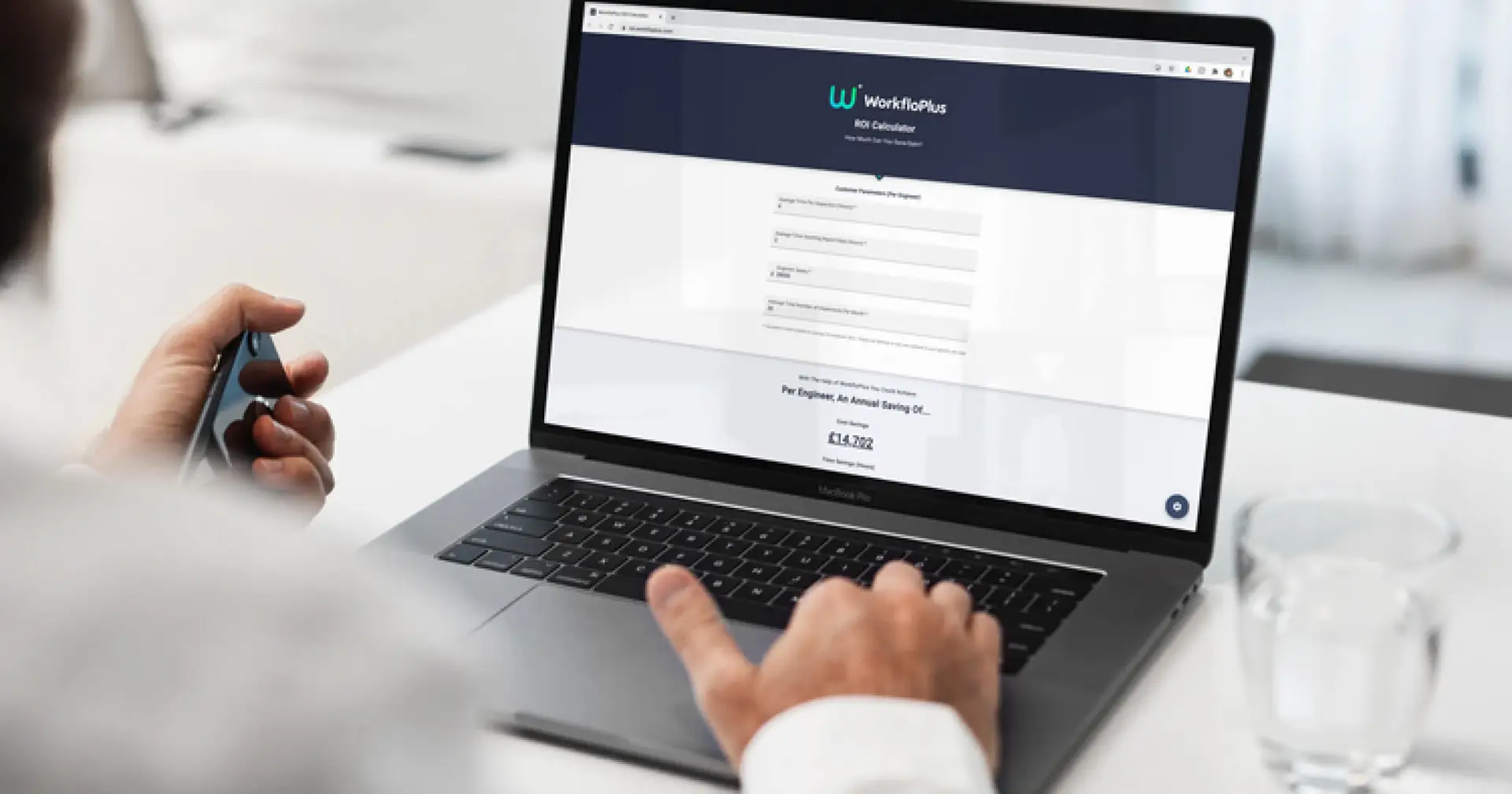

By reducing paper within your business and connecting frontline workers using portable devices integrated with digital workflow software such as Intoware’s WorkfloPlus, you will see immediate bottom-line improvements. Use our ROI CALCULATOR to find out how?

Investing in connected working to change how you work leads to better decision making, profitability and future resilience. See how with these ‘Top-Tips’.

Here’s 10 reasons to go digital

1) Real-Time Data

Putting physical manuals and tick-lists into a digital format can streamline business processes. It enables easy access to ‘real-time’ data that flows across your business as part of a connected worker strategy to maximise performance.

2) Switch to digital workflows

You can build a huge bank of data and use the same information to predict when failures may occur. In heavy industry, H&S, compliance, and audit checks are frequent and detailed. Unless these processes are done digitally, they create huge volumes of paper that are difficult to track and measure accurately.

3) Remove Data Silos

Typically, data is recorded but scattered in data silos or manual processes. It is difficult to access and pass freely between systems, preventing the possibility of better, connected working.

4) Reduce Human Errors

We all make mistakes we’re only human! We accidentally delete files or take short-cuts to get the job done quickly. The opportunity to make these types of mistakes is significantly reduced with digital workflow instructions.

5) Increase Productivity

Your frontline workers will complete their jobs in a shorter time to a higher quality. By providing the right data when needed, you can reduce the time need to make decisions. This allows workers to determine what is needed and what actions should be taken.

6) Empower Continuous Improvement

It’s not just about efficiencies – it’s about taking a granular view into operations. Connected working provides access to better supporting data for strategic decision making. By taking data from various sources, your workers can analyse information to help predict failures based on historical trends. This makes a huge difference when it comes to limiting downtime.

7) Minimise Equipment Downtime

Streamlining asset maintenance tasks means therefore, that machines are available 100% of the time.

8) Eliminate Admin

Using digital workflows to follow instructions frees workers up from mundane data entry tasks so they have more time to carry out more important tasks.

9) Ensure Compliance

Constantly changing compliance needs are met by checking ‘who’, ‘did’ ‘what’ and ‘when’ with a ‘single source of truth’. This is achieved by digitising inspections.

10) Improve Safety

Safety improves as businesses can function with fewer staff out in the field. This is helpful when frontline workers are completing complex asset inspections in remote or hazardous environments.

In Conculsion

By digitising critical processes and providing the digital ‘tools’ frontline workers need is the key to unlocking productivity, cost efficiencies, and compliance. Intoware did just that for Petrofac. It gained a 200% productivity increase by digitising North Sea inspections with WorkfloPlus, wearables from RealWear and digital twin technologies.