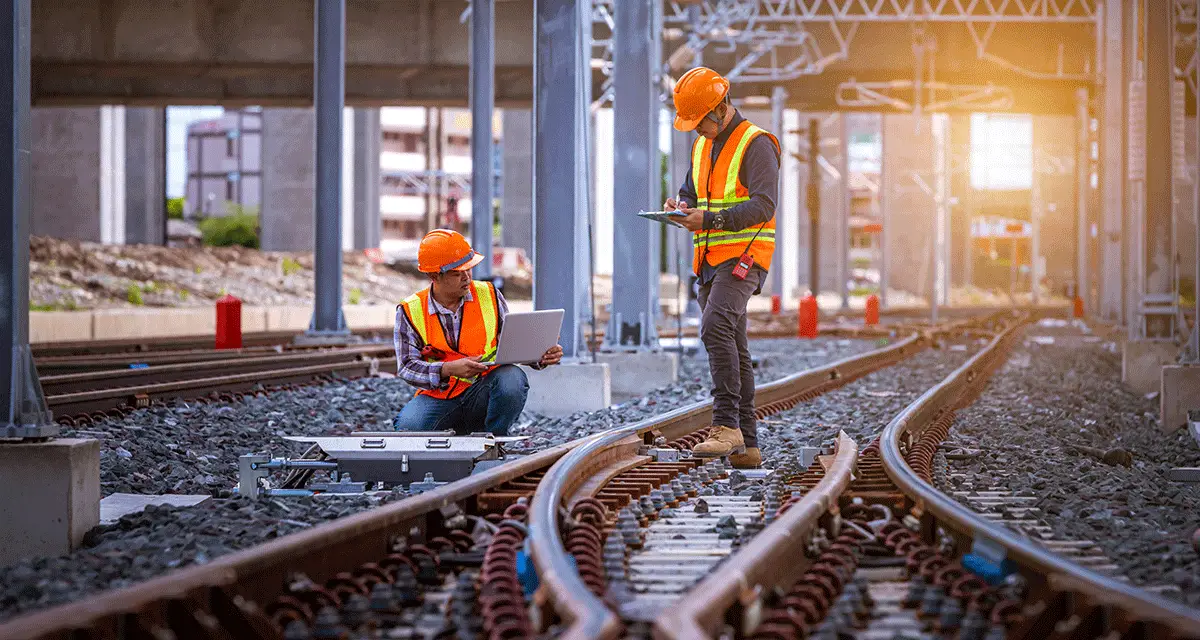

Intoware, the leading digital workflow provider, has transformed critical rail track renewal processes. This paves the way for future deployment with frontline maintenance teams.

Designed to support a 10-year program, this initiative actively aims to positively impact track design, deployment, and renewals. The Central Railway Systems Alliance (CRSA) collaborates with Network Rail R&D to accelerate rail infrastructure regeneration. Specifically, they focus on the London North West, London North East, and East Midlands routes.

Currently, this digitalisation trial at Network Rail’s Aston Depot integrates innovative solutions. Its primary goal is to standardise data collection and reporting for safety-critical renewals. By converting legacy paper-based processes into a user-friendly and adaptable ‘connected worker‘ solution, the project enhances efficiency significantly.

Last year, Network Rail’s Accelerated Innovation program reached out to Intoware. They realised that information on track renewals was neither fully captured nor efficiently used across the business. So, by digitising data and processes for frontline teams, they aim to deliver high-quality information. This improves track safety and reduces costs.

Hands-Free Working

To achieve this, the digital automation platform WorkfloPlus was selected. It effectively converts paper-based workflows into simple, step-by-step digital work instructions. Workers can easily access these instructions via wearable head-mounted tablets (HMTs). These feature augmented reality from RealWear, forming an integral part of the connected-worker solution.

“Workers can operate completely hands-free using voice-controlled headsets,” said Chloe Denham, program manager for innovation and continuous improvement at the Central Railway Systems Alliance. “Moreover, they can collect data supported by images, videos, emergency calling, and GPS integration. This enables reliable referencing and a consistent approach to renewals.”

Keith Tilley, Intoware’s CEO, expressed his enthusiasm about partnering with Network Rail. “The challenge for the trial involved reducing print costs while avoiding lengthy delays caused by paper processes. Most importantly, improving data quality proved critical. This effort significantly reduced the amount of incomplete intelligence. Consequently, it minimized the need for further inspections to recapture missing information. This ensures track safety and compliance.”

“Additionally, WorkfloPlus enhances the quality of data captured by auto-generating reports in real time from inspections,” Keith added. “As a result, this information is instantly shared with colleagues and supervisors, delivering significant performance improvements. Furthermore, hands-free working enhances situational awareness, making it easier for the workforce to identify potential hazards.”