Digitalisation is essential for driving efficiency, improving safety, and maintaining compliance across the rail sector.

WorkfloPlus is the perfect tool for the rail industry, providing frontline teams with real-time data, streamlined workflows, and powerful insights to optimise operations and protect workers at every level.

Whether you’re managing track maintenance, infrastructure upgrades, or rolling stock inspections, WorkfloPlus helps you deliver consistent, high-quality results while enhancing worker safety and operational efficiency.

Identify hazards, upgrade safety protocols and action threats quickly.

WorkfloPlus provides frontline teams with consistent data, standardised processes, and powerful insights to improve both on-site operations and office based decision-making. By digitising key processes, you ensure that every task is performed safely, accurately, and in line with industry regulations.

The rail sector faces constant pressure to improve safety standards, reduce downtime, and increase operational efficiency.

WorkfloPlus provides rail operators and maintenance teams with a digital solution to identify hazards, upgrade safety protocols, and action threats quickly and effectively. By replacing paper-based processes with digital workflows, it ensures consistent operations and reliable data across all rail projects.

Rail operations require precision and real-time information to prevent disruptions and ensure smooth performance. WorkfloPlus equips teams with the tools to capture accurate data, follow standardised procedures, and access critical information instantly. Empowering both frontline and back-office teams to work more effectively.

Our technology streamlines training, inspections, and health & safety and provides real-time information across you operations.

Guarantee Compliance

Guarantee Compliance

Safety is a top priority in the rail industry, where teams work in challenging environments and face high-risk tasks daily. WorkfloPlus helps reduce potential hazards before they become threats by providing real-time data and step-by-step digital guidance to frontline teams.

By digitising safety protocols, WorkfloPlus ensures that workers follow the correct procedures every time, minimising human error and improving overall safety outcomes. Teams can instantly capture and report hazards on-site, triggering immediate action to prevent accidents and operational disruptions. Remote inspection technology further enhances safety by allowing teams to assess high-risk areas, such as track infrastructure and overhead lines, without direct exposure to danger.

For example, Network Rail successfully reduced the need for visual checks of overhead powerlines by using WorkfloPlus with drone technology—keeping frontline workers safely on the ground while improving the accuracy and efficiency of inspections. By integrating real-time safety data into day-to-day operations, WorkfloPlus ensures that your workforce remains protected at every stage of the job.

Meeting industry standards and regulatory requirements is critical in the rail sector, where operational failures can have significant safety and financial consequences. WorkfloPlus replaces outdated paper-based checklists with automated digital workflows, ensuring that every task is performed according to the latest guidelines and that a full audit trail is automatically created for compliance purposes.

WorkfloPlus provides real-time version control, so any updates to safety regulations or operational procedures are immediately reflected in the workflows used by frontline teams. This prevents outdated practices from creeping into daily operations and ensures consistency across maintenance, repair, and inspection processes.

By capturing compliance data at the point of work, WorkfloPlus creates a clear, traceable record of every action performed. This makes regulatory audits faster and more accurate while giving rail operators the confidence that all procedures are being followed correctly. The ability to monitor and analyse compliance data in real-time also helps identify gaps and implement improvements before they become issues.

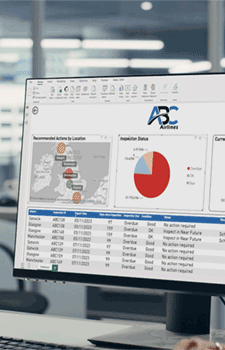

Accurate and timely data is essential for maintaining smooth and efficient rail operations. WorkfloPlus removes information lag by capturing and transmitting data instantly as tasks are completed, ensuring that decision-makers have immediate access to the latest insights.

By standardising how data is collected and reported, WorkfloPlus ensures that teams are working with consistent, high-quality information. This improves the accuracy of performance monitoring and helps identify operational bottlenecks and areas for improvement. Real-time visibility into site operations and asset performance enables faster, more informed decision-making, reducing downtime and improving overall service reliability.

WorkfloPlus also enhances predictive maintenance by providing detailed data on asset condition and performance. This allows rail operators to identify potential failures before they occur, schedule maintenance proactively, and avoid costly service disruptions. By integrating real-time data into daily operations, WorkfloPlus helps rail companies increase efficiency and reduce operational risks.

Maximising workforce productivity is key to meeting the growing demands on the rail network. WorkfloPlus streamlines complex processes by replacing manual tasks with automated workflows, reducing downtime and eliminating inefficiencies.

By providing workers with real-time guidance and instant access to critical information, WorkfloPlus ensures that tasks are completed correctly the first time, minimising rework and improving overall job completion rates. Digital work instructions standardise how tasks are performed, reducing variability and ensuring that even complex processes are carried out consistently.

Training new staff becomes faster and more effective with WorkfloPlus, as digital guidance provides step-by-step support directly within the workflow. This shortens the learning curve and ensures that all team members – regardless of experience level – can contribute to operations quickly and confidently.

Rail infrastructure and rolling stock require regular maintenance and inspection to ensure safety and performance. WorkfloPlus enhances inspection processes by allowing teams to capture photo and video evidence directly within the workflow, ensuring accurate and verifiable records.

Inspection data is transmitted instantly to the back office, enabling faster decision-making and more effective resource allocation. Automated checklists and guided workflows ensure that no step is missed, reducing human error and improving the accuracy of maintenance records. The ability to access historical inspection data also helps identify patterns and prevent recurring issues, leading to improved long-term asset performance.

WorkfloPlus helps rail companies implement predictive maintenance strategies by providing real-time insights into asset condition. This allows maintenance teams to schedule repairs before failures occur, reducing downtime and improving service reliability.

Training is essential in the rail industry, where new technology, evolving regulations, and workforce turnover create constant challenges. WorkfloPlus captures the expertise of experienced team members and embeds it into digital workflows, creating a structured and consistent training process.

New employees can follow guided, step-by-step instructions to complete tasks correctly, reducing the time it takes to get up to speed and improving overall competence across the team. By embedding training into day-to-day operations, WorkfloPlus ensures that learning happens in the flow of work, making it more effective and less disruptive.

Experienced workers can also update and refine workflows as processes evolve, ensuring that training materials remain relevant and accurate. This approach helps preserve institutional knowledge and make it easily accessible to all team members, reducing the risk of knowledge loss due to staff turnover.

The rail sector is rapidly evolving, with new technology transforming how operations are managed and executed. WorkfloPlus helps rail companies stay ahead by providing a flexible and scalable platform for digital transformation.

By automating routine tasks, improving data accuracy, and enabling real-time decision-making, WorkfloPlus helps rail companies reduce operational costs, improve service reliability, and enhance customer satisfaction. The ability to adapt quickly to changing demands and technological advancements gives rail operators a competitive edge in an increasingly complex and fast-moving industry.

On our Discovery call, we’ll find out about you and your existing processes to learn exactly what you’re looking for.

Configure your workflows. Customise templates with our toolkit or collaborate to build processes from scratch.

Integrate your digital workflows with existing devices. We’re on hand to help with training, support and integration.

WorkfloPlus by Intoware, simplifies and standardises even the most complex task – whatever industry you are in.

Compliance

Work Instructions

Inspections

Training

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.