Despite an ever-changing regulatory landscape complicated by Brexit and the risk of penalties which is unlikely to lessen post-pandemic, firms are re-thinking their approach to compliance and corporate risk. Here Brad Flook, CRO, Intoware explains how new digital ‘tools’ can safeguard your business and deliver a competitive advantage.

Managing compliance checklists can be challenging, particularly if you are a large business with geographically dispersed sites. Differing local regulations increase complexity. This means in some cases different processes must be implemented, making operations costly. The ability to report on compliance accurately with granular and timely data has become an increasing priority for managers as the UK enters this new post-Brexit era.

For effective compliance you need precision, to be systematic and you need to be up to date. This can be done using spreadsheets or pen, paper and clipboards. But these methods require human input and humans make mistakes. However, if you have digital ‘tools’, they can take away the hassle of managing compliance processes. This mitigates the risk of failure, saves you from having to remember everything, and facilitates a more proactive approach to compliance.

Digitise Procedures to Ensure Compliance

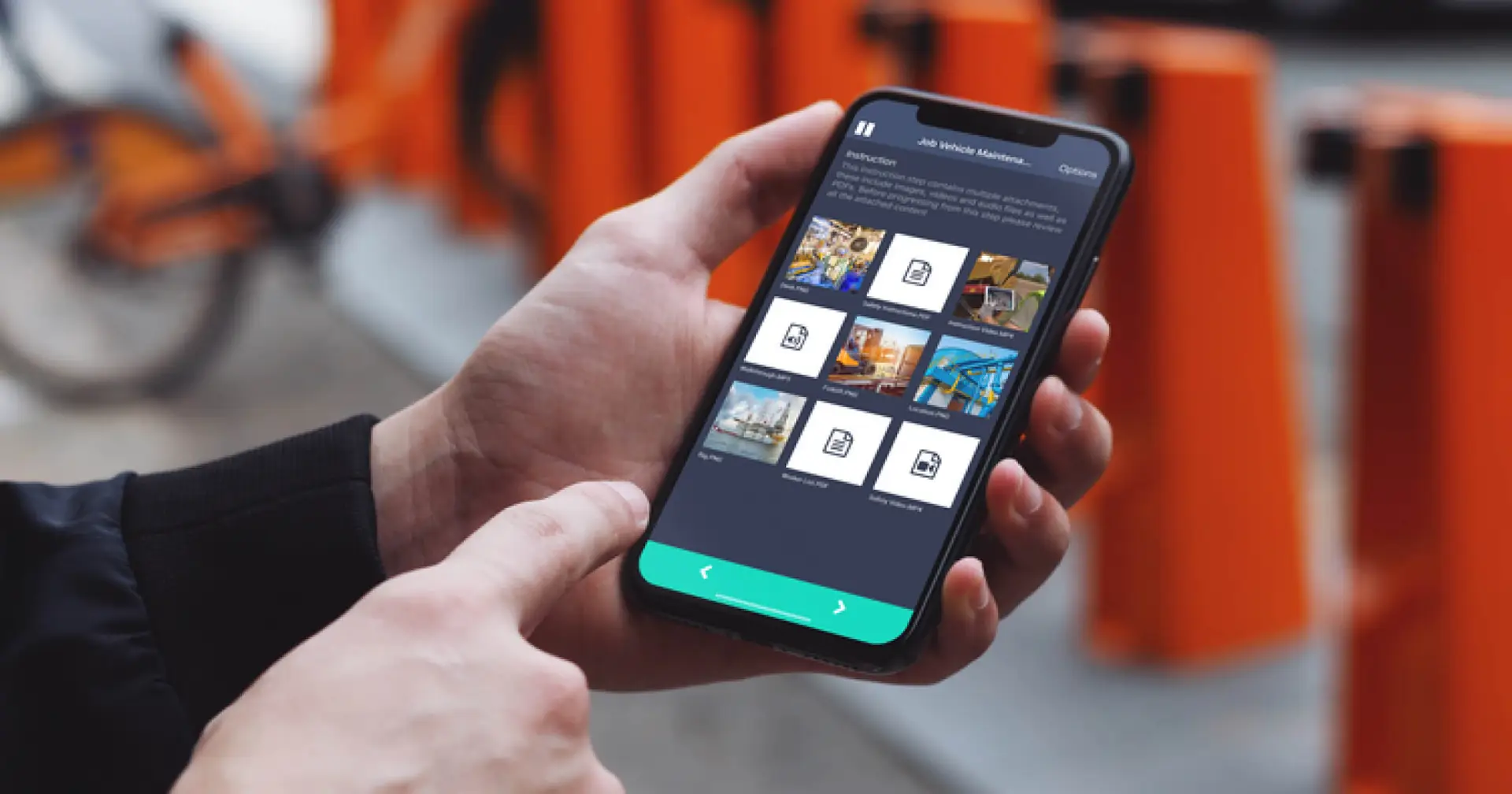

Health and safety procedures, compliance and audit checks in industrial environments are often frequent and detailed. Unless these processes are digitised, they create a huge volume of paper that is difficult to track and impossible to measure accurately. Done digitally, however, anybody from the worker to the supervisor or auditor can see the characteristics of a check-in ‘real-time’. You can understand the impact it has and receive digital evidence, such as photos, videos or data, to know if it’s done correctly – all in a fraction of the time.

Prior to the pandemic, at Intoware we developed the automation platform WorkfloPlus using mobile and AR technology from our partner Realwear. This was to digitise audit, compliance and manufacturing processes. By switching to digital instructions, manufacturers can build a huge bank of data for machine audits. They can also predict when failures in manufacturing or assembly processes may occur.

Automatic Evidential Capture

The capture, analysis and utilisation of this knowledge are, therefore, a real ‘game-changer’. By providing real-time data capture, workflow technology is allowing analytics to deliver new insights. This helps deliver greater efficiencies, cuts costs and drives innovation.

WorkfloPlus ensures better compliance by providing a thorough audit trail of ‘who’, did ‘what’, ‘where’ and ‘when’. It catalogues every decision point and action in industrial operations. So, there are fewer errors and at the same time, it enables improved productivity.

The speed of change is rapid too. A change to the business process is sent by WorkfloPlus to all users instantly. It provides a “single source of truth”. It’s not sent as a paper trail, so everyone is working off the same version. This means it’s easier to schedule downtime and manage production demands as things change. But if you’re relying on spreadsheets or written notes, this change could take many days or even weeks.

But how do these technologies help safeguard when operating, inspecting and maintaining equipment, particularly during the pandemic?

Safeguarding your business with collaborative working

Here is a frontline worker scenario: At the manufacturing plant, Sarah wears her HMT-1 (head-mounted tablet) attached to a hard-hat to be allowed access to the site. Once inside she logs on securely through her wearable device so she can work ‘hands-free’. She receives voice commands from her manager at HQ with guided instruction via indoor maps that provide her with the locations of her colleagues to ensure that social distancing is always maintained.

Sarah walks to the machinery for a routine inspection. Having found a faulty component, she searches for information on the specific part she needs to pick up from the storeroom. Before starting the repair, she’s given important safety instructions. As Sarah is a new recruit, she also benefits from a live two-way video call with her supervisor to get valuable hands-free coaching advice. Sarah also receives step-by-step visuals and guided work instructions that help her to safely finish the job. Once completed, she updates the system so it’s clear ‘who’ did ‘what’ and ‘when’. This is shared with her co-workers providing a thorough feedback loop.

Currently, government rules state that it’s not safe to be within two meters of another person. We won’t be able to touch our devices without wiping them down when doing an inspection. Covid-19 has made everything more challenging, so contactless solutions such as ‘hands-free’ headsets are increasingly being used to safeguard lives.

Digital GxP (good practice) compliance

WorkfloPlus can help to ensure good practice for specific industry standards and protocols too. An example is GxP compliance required for laboratory work and food, medical device and cosmetic manufacturing.

GxP describes Good (x) Practices, where (x) is a particular field, e.g., food manufacturing. They are most prevalent in the medical and food industries. These practices are shaped by regulatory requirements and industry standards to create a body of knowledge. This determines how outcomes are achieved and quality requirements are upheld. Strict adherence to these standards through established practices is essential if you are to continue to operate.

With WorkfloPlus you can ensure good practice by providing the right ‘tools’ to deliver process visibility, control and accountability across your operations. This ensures your processes are always ‘fit for purpose’ and there is no variation in product quality. The ability to meet rigorous GxP standards allows firms to move with confidence in highly regulated fields. This ensures the integrity of their processes and effective operation.

Summary

As most industries face similar challenges and risks to their competitors. Knowing more about compliance and industry standards and protocols, when they might occur and the consequences of failing to manage them effectively, will enable you to stay ahead of your competitors.

Firms can consider each requirement on the horizon and assess each one, based on their priorities and the volume of work involved in addressing them. This enables a competitive advantage over those businesses that don’t manage compliance in this way. The value of this to any business cannot be underestimated.