In the renewable energy sector, wind turbine inspections play a crucial role in maintaining efficiency and safety. Inspectors often face challenging and hazardous environments, so they need hands-free technology to perform their tasks effectively. WorkfloPlus, on RealWear wearable devices, revolutionises the inspection process by allowing workers to operate safely and accurately while keeping their hands free.

Why Choose WorkfloPlus for Wind Turbine Inspections?

With WorkfloPlus, you can ensure that every inspection is conducted with 100% accuracy. This enhances both safety and compliance. Here’s how it works:

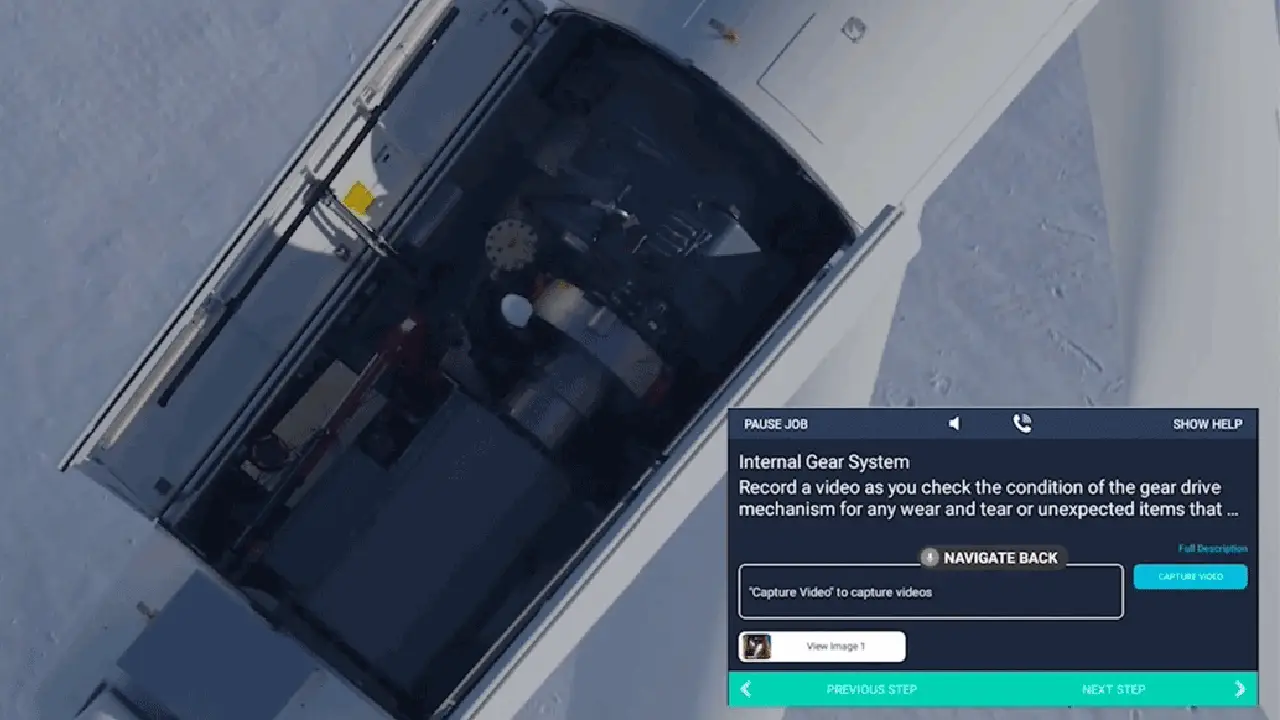

- Hands-Free Operation – Using RealWear’s wearable technology, inspectors can access step-by-step digital work instructions and checklists without needing to hold a device. This allows them to focus on the inspection process while keeping their hands free for tools and equipment.

- Instant Proof of Work Reporting – WorkfloPlus enables real-time documentation of completed tasks, allowing workers to capture evidence, photos, and notes directly into the system. This ensures that all inspection details are logged accurately and instantly, facilitating faster invoicing and compliance reporting.

- Enhanced Safety Measures – By streamlining the inspection process, WorkfloPlus reduces the risk of errors and accidents. Workers can complete inspections confidently, knowing they have access to the latest safety rules and regulations.

- Data-Driven Insights – The platform captures comprehensive data from each inspection, allowing teams to analyse performance and identify areas for improvement. This proactive approach helps optimise maintenance schedules and reduce downtime.

Transform Your Inspection Procedures Today

Discover how WorkfloPlus and RealWear can enhance your wind turbine inspection process, ensuring safety, efficiency, and compliance.

Contact us today to explore how WorkfloPlus can elevate your wind turbine inspection practices.